Home

>

products

>

Copper Pipe Tubes

>

Home

>

products

>

Copper Pipe Tubes

>

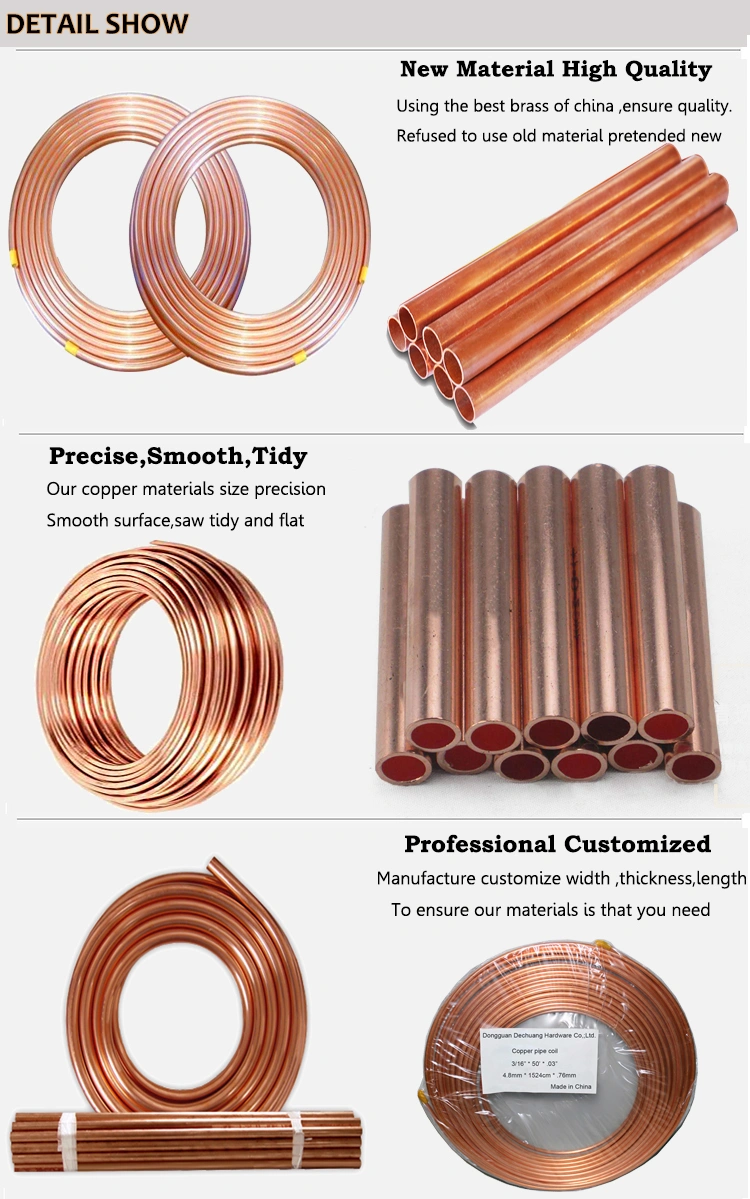

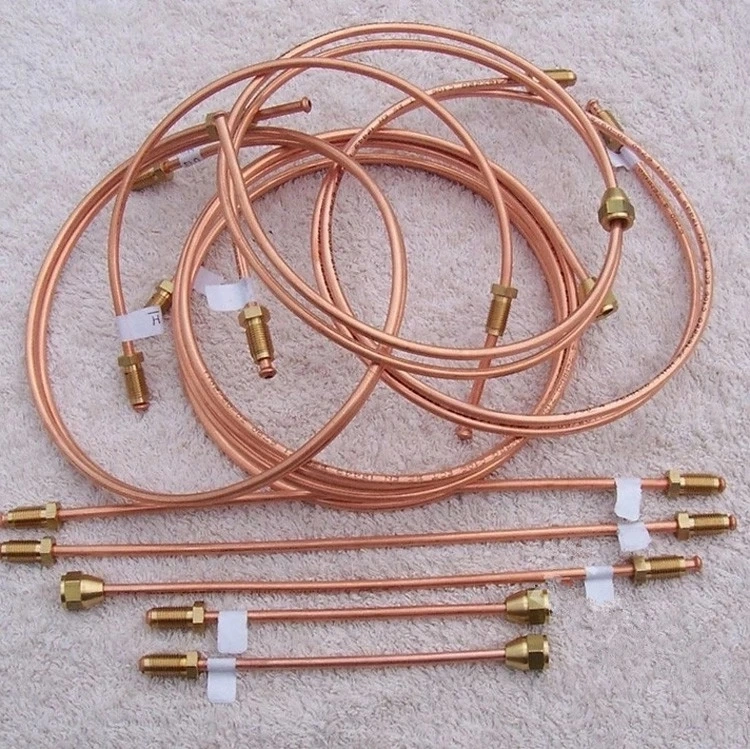

99.99% Wickes 28mm Copper Pipe Tubes JIS C10200 Building Materials

Product Description

| Copper Tube | |

| Material | C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920,C10930,C11000,C11300,C11400, C11500,C11600,C12000,C12200,C12300,TU1,TU2,C12500,C14200,C14420,C14500,C14510,C14520,C14530, C17200,C19200,C21000,C23000,C26000,C27000,C27400,C28000,C33000,C33200,C37000,C44300,C44400, C44500,C60800,C63020,C65500,C68700,C70400,C70600,C70620,C71000,C71500,C71520,C71640,C72200. |

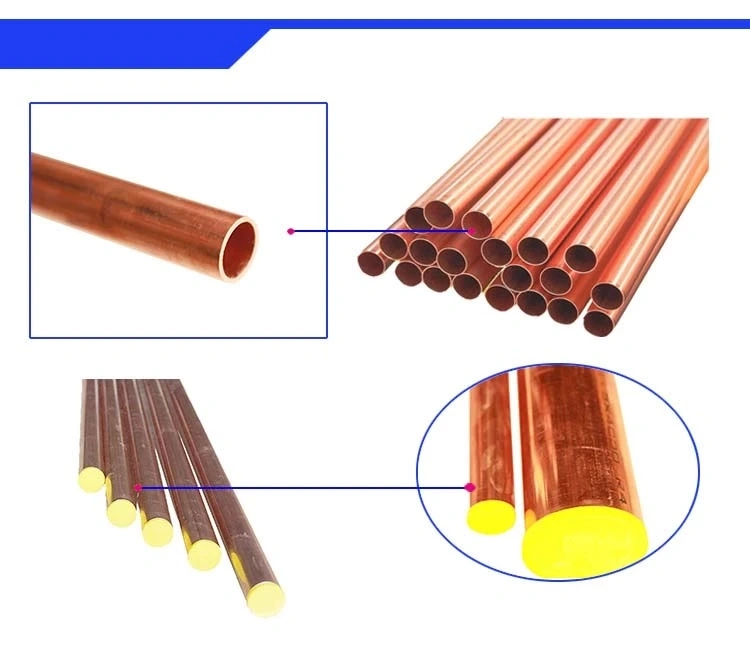

| Shape | Round, square, rectangular, etc. |

| Round | wall thickness :0.2-120MM outside diameter :2MM -910MM |

| Square | wall thickness :0.2-120MM size :2MM ~2MM -1016MM ~1016MM |

| Rectangular | wall thickness :.2-910MM size :2MM -4MM ~1016MM -1219MM |

| Length | 5.8m, 6m, 11.8m, 12m, or as required. |

| Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard,soft,etc |

| Surface | mill,polished,bright,oiled,hair line,brush,mirror,sand blast,or as required. |

| Delivery time | 10days after received the deposit of T/T or L/C |

| We can make any size according to your requirement . | |

Composition : CuNiSi

Characteristics : 1, High hardness

2, Good mechanical strength

3, Heat treatable copper alloy

Hardness(HRB) : ≥90

Conductivity%(IACS): ≥48

Applications : 1, Resistance welding tips/welding wheels/fixtures,stud welding collects/tips.

2, Cavities for injection molds.

3, hot runner systems for injection molds.

4, Welding die.

5, Heat sink inserts in steel plastic molds.

6, electrode holders etc.

Forms available :

Round/rectangular bars : 1-150mm(diameter)

Plates : 8-150mm(thickness)

Hexagons : A full range

Other forms : Available upon request

======================================================================

Description of 5N copper and 5N copper products:

======================================================================

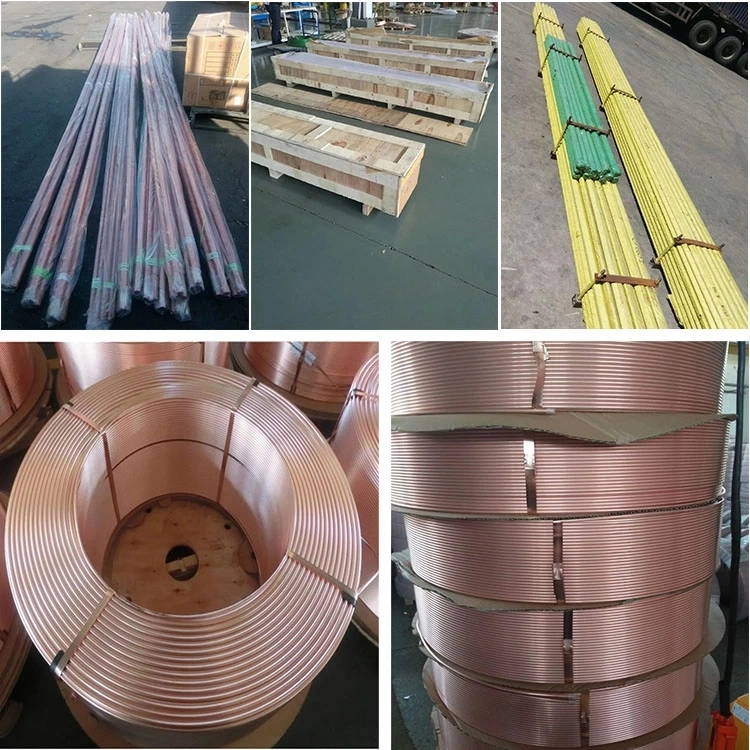

Packaging & Shipping

Packaging of copper cathode sellers:

Inner-packing: vacuum-packed,wrapped with styrofoam.

Outer-packing: carton/plywood.

Shipping of copper cathode sellers:

======================================================================

We can supply you the translation methods whatever you want.

--By express (DHL/Fedex/etc.)

--By Air to your nearest Airport

--By Sea to your nearest Seaport

--By the sellers' shipping agent

======================================================================

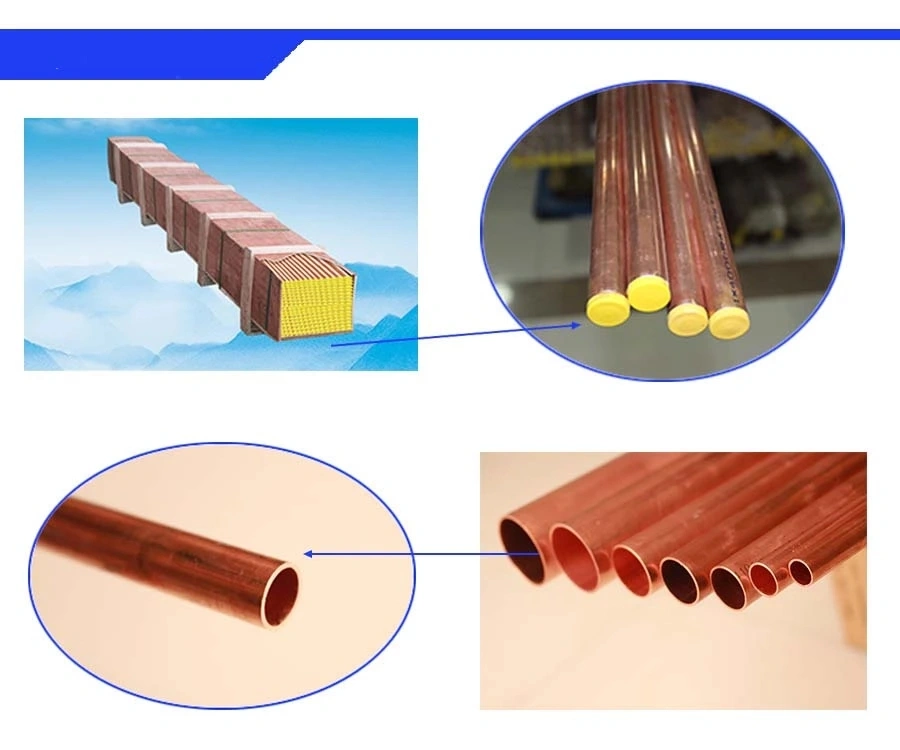

How to produce

The first step ,our Technical put the materials into Vacuum Induction Melting produce.

The second step, engineering team analysis the chemical of materials.

The third step,Our team will put them into the rolling / annealing produce.

The fourth step,them are put into the machining process.

And then ,keeping their dimension.

We have huge experience, expertise in Copper Pipe and the best dedicated team to deliver best quality products delivered as well as services at the most affordable prices for Copper Pipe . We are looking ourselves as good business partners for customers and are looking forward to establish long term professional relationship. With our world class manufacturing facilities to Copper Pipe .

we are able to deliver on time for all grades of Copper Pipe . Our stock house always has storage capacity for keeping lots of order from our clients. We make sure that the packaging of ordered materials is done in the best way.

Although lots of options are available in the market, we still stand apart in the market in the field of manufacturing, packaging and export of our products. What really makes us different from others is our commitment to quality. With a vast experience of over four decades in manufacturing of pipes and tubes, we have great expertise and technical edge for the manufacture.

Contact Us at Any Time